Reusing Wood in Concrete Formwork: Is It Safe? Complete Guide to Wooden Shuttering and Best Wood Types for Columns and Foundations

A comprehensive guide on reusing wood in concrete formwork for columns and foundations. Includes whether reusing wooden shuttering is right or wrong, best wood types for pouring like plywood and film-faced formwork, the honeycombing problem and its causes and solutions, differences between wooden and steel formwork, number of uses, maintenance and storage tips, and advantages and disadvantages of each type.

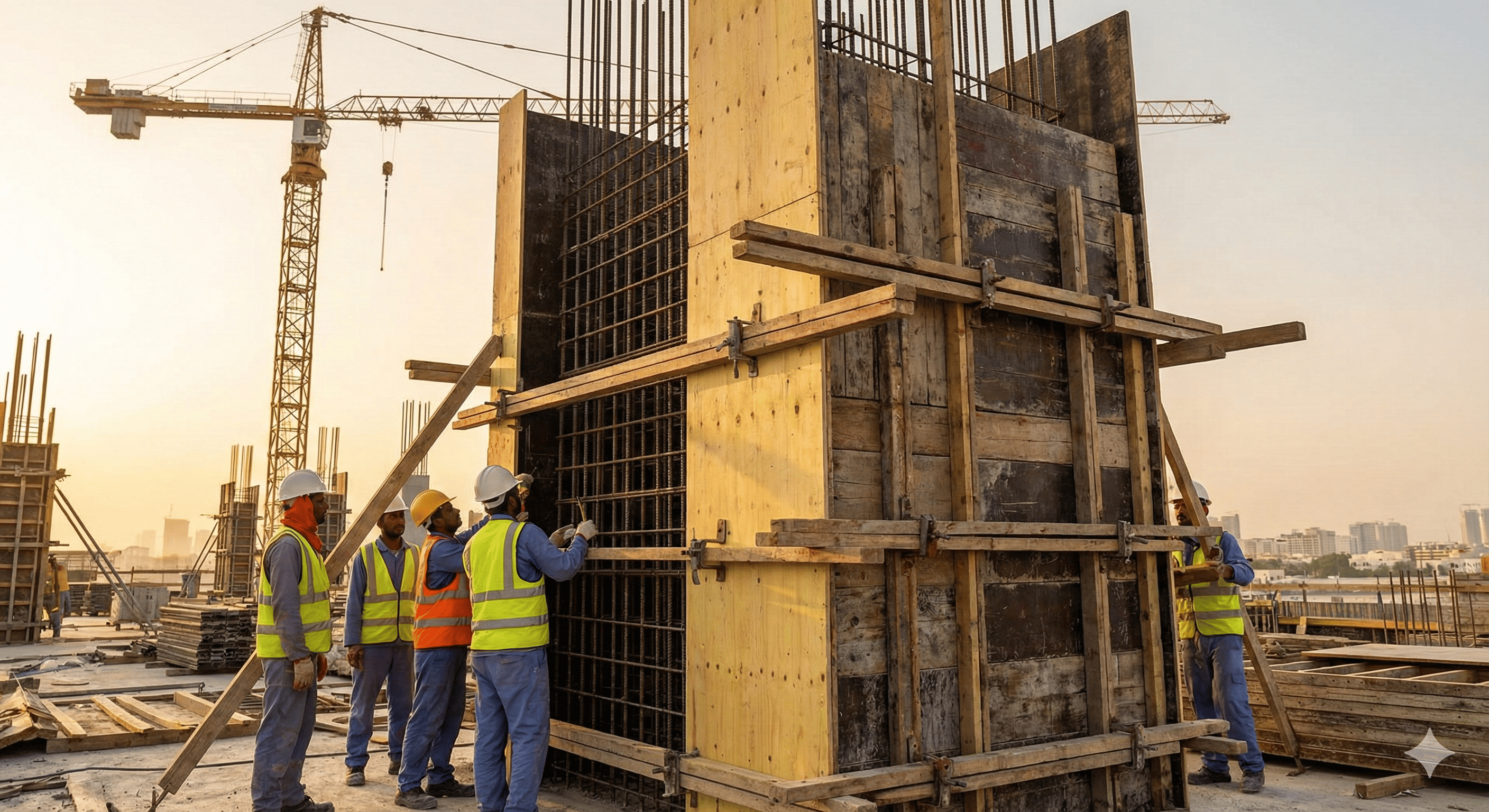

Introduction: The Importance of Wooden Formwork in Construction

Wooden formwork is the backbone of any successful concrete pouring operation. These are the temporary molds that hold fresh concrete until it hardens and gains strength. With rising construction costs, many contractors resort to reusing wood across multiple sites or properties to save money. But the important question that many owners and engineers ask is: Is this practice correct and safe, or could it cause serious problems like honeycombing and weak concrete?

In this comprehensive guide, we will answer all these questions in detail. We will cover the types of wood used in pouring, the best quality options, the allowed number of uses, and when wood should be replaced. We will also explain the serious honeycombing problem, its causes, and how to avoid it. And we will compare wooden and steel formwork so you know which is better for your project.

What is Wooden Formwork?

Wooden formwork is a temporary structure designed in a specific way to fit the shape of the required concrete element, whether it's a column, foundation, slab, or beam. Concrete is poured inside this structure and it remains until the concrete hardens and bonds sufficiently to support itself, then the wood is removed and reused for another pour.

Wooden formwork consists of several basic elements including boards in contact with concrete, vertical props, braces, crossbeams, metal clamps, and base plates. Each element has a specific role in securing the mold, preventing concrete leakage, and ensuring accurate dimensions.

Is Reusing Wood in Concrete Pouring Correct?

The short answer is yes, wood can be reused in concrete pouring, but with specific conditions and a limited number of times depending on the type of wood, its quality, and how it's maintained.

Number of Uses by Wood Type

Regular timber boards can be used only 4 to 6 times before they start deteriorating and cracking. Standard B-B grade plywood can handle up to 5 to 10 pours with proper care. MDO phenolic-coated plywood can handle 10 to 25 pours. High-density HDO film-faced plywood can handle 20 to 50 pours or more with good maintenance. Some specialized plywood types can reach 100 uses with ideal care.

When Wood Should Be Replaced Immediately

Wood should be replaced when visible cracks appear in the boards or when there's swelling due to water absorption. Also when the outer layer of coated plywood is peeling or when gaps appear between boards allowing cement morite to leak. If the surface becomes rough and worn in a way that affects concrete smoothness, it should be replaced. Also when there are many holes from previous nails weakening the board.

Risks of Using Worn-Out Wood

Using old and worn wood can lead to serious problems affecting building safety. The most dangerous is honeycombing which significantly weakens concrete. Cement mortar may leak from gaps leaving exposed aggregate. Column or foundation dimensions may deviate from required measurements. Concrete surface quality may be affected and need costly repairs.

Types of Wood Used in Concrete Formwork

The types of wood used in formwork vary according to quality, price, and number of uses. Understanding these types helps you choose the most suitable for your project.

Traditional Timber Boards

This is the most common and cheapest option for small and medium projects. It comes in 2.5 cm thickness and 10 to 20 cm width. Easy to cut and shape without special skills. However, it absorbs water from concrete which may affect its strength. Its lifespan is short at only 4 to 6 uses. It leaves gaps between boards that appear on the concrete surface. Suitable for work that doesn't require high-quality finishing.

Plywood

Plywood consists of multiple layers of wood veneer glued perpendicular to each other for increased strength. It comes in large sizes that reduce the number of joints in concrete. Stronger and more stable than regular timber. Gives a smoother concrete surface. Can handle 8 to 15 uses depending on quality. Available in different thicknesses from 12 to 21 mm. The 18 mm thickness is most commonly used in formwork.

Film-Faced Plywood

This is the best option for large and repeated projects. Plywood is coated on both sides with a layer of phenolic or melamine resistant to water. The surface is very smooth giving excellent concrete finishing. Resistant to moisture and chemicals in concrete. Can handle 20 to 50 pours or more with care. Easy to clean after each use. Concrete doesn't stick to it thanks to the smooth layer. More expensive than regular plywood but economical in the long run.

Types of Coated Plywood

MDO which is Medium Density Overlay with a medium-density layer and handles 10 to 25 pours. HDO which is High Density Overlay with a high-density layer and handles 20 to 50 pours or more. Black or brown film is the most common in markets. Some types come with printed grid lines to facilitate measuring and cutting.

Melamine Coated Plywood for Formwork

Melamine-coated plywood is sometimes used in formwork for its smooth surface. It gives a smooth concrete finish without the need for leveling work. But it's more expensive than regular plywood. Suitable for visible surfaces that need high-quality finishing.

Softwood Timber

Includes pine and spruce woods which are available and lightweight. Easy to cut and shape but less durable. Usually used for props and crossbeams, not for surfaces in contact with concrete. Suitable for small one-time projects.

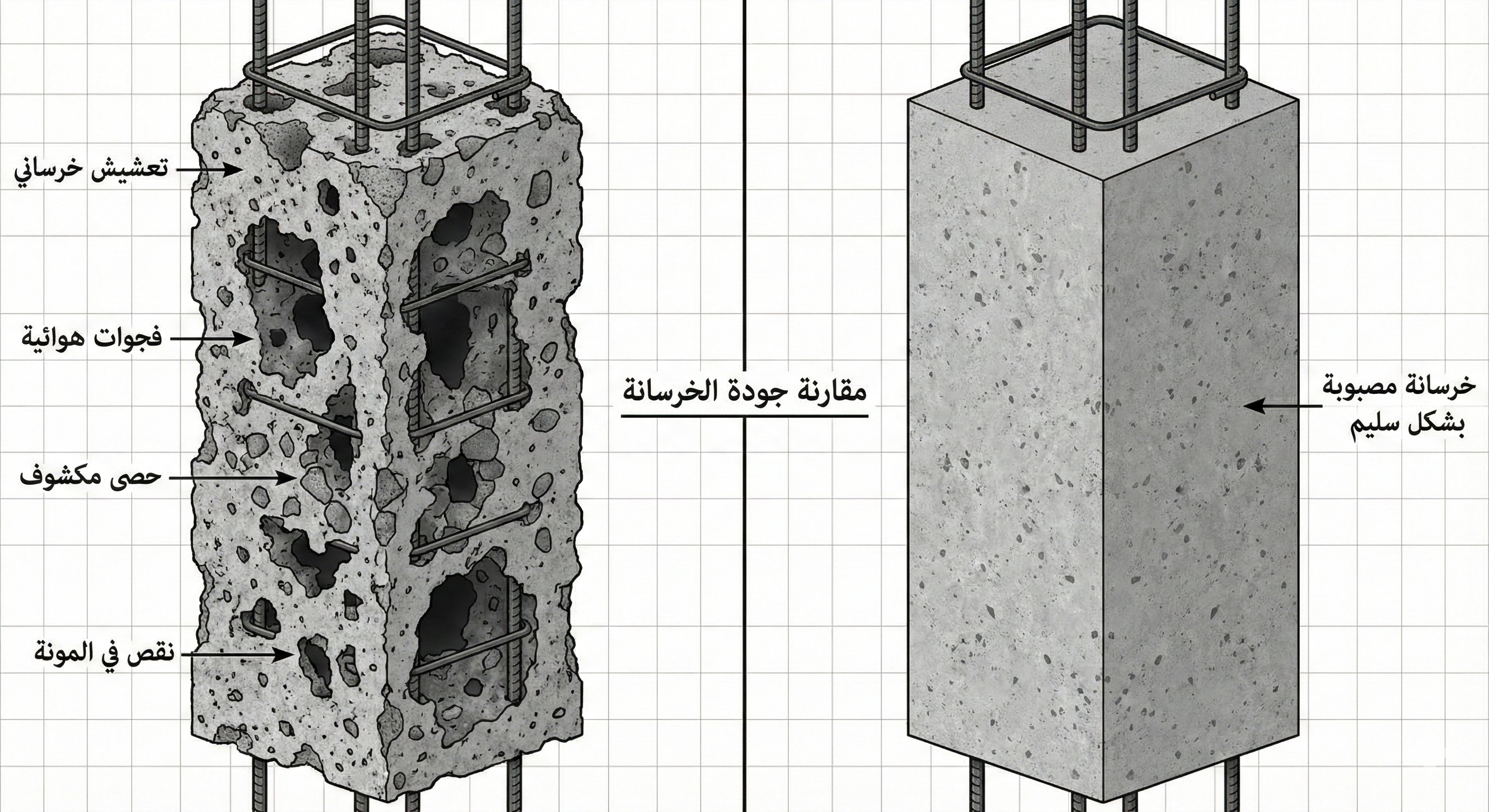

Honeycombing in Concrete: The Greatest Danger

Honeycombing is the most dangerous defect in reinforced concrete. It appears as voids and cavities on the concrete surface resembling a honeycomb. These voids significantly weaken concrete and expose reinforcement steel to rust and in severe cases may lead to collapse of the concrete element. This is why engineers call it concrete cancer.

Causes of Honeycombing Related to Wooden Formwork

Openings and gaps in the wooden formwork allowing cement mortar to leak out and leaving exposed aggregate. Using worn and deteriorated formwork that doesn't seal properly. Obstacles inside the formwork from wood remnants or any materials preventing concrete from reaching all parts. Formwork not suitable for the element being poured in terms of dimensions and fixation. Formwork designed in a way that doesn't allow air to escape during pouring and compaction.

Other Causes of Honeycombing

Not using a vibrator sufficiently during pouring to remove air bubbles. Dense reinforcement steel and bars too close to each other preventing concrete flow. Pouring concrete from a height of more than 1.5 meters causing component separation. Using a very dry or non-homogeneous concrete mix. Delayed concrete arrival and beginning of hardening before pouring.

Danger of Honeycombing to the Building

Honeycombing reduces the effective cross-sectional area of the concrete element which weakens its load-bearing capacity. It exposes reinforcement steel to external factors like moisture and oxygen leading to rust. It significantly reduces the building's lifespan. In severe cases, it may require demolition and complete re-pouring of the element. Honeycombing in columns is more dangerous than in other elements because columns bear the entire building load.

How to Avoid Honeycombing

Use wooden formwork in good condition and tightly sealed without gaps. Ensure the formwork is clean of any obstacles before pouring. Use the vibrator correctly and regularly during pouring. Pour concrete in small batches of 50 cm with compaction after each batch. Don't pour concrete from a height exceeding 1.5 meters. Use a homogeneous concrete mix with appropriate workability. Tap on the formwork from outside during pouring to ensure concrete reaches all parts.

Treating Honeycombing

Simple surface honeycombing can be treated by cleaning the area and filling it with strong cement mortar or grout material. Medium honeycombing requires removing weak parts and refilling with specialized repair materials. Large honeycombing especially in columns may require complete demolition and re-pouring because any patching attempt may be unsafe. A structural engineer should be consulted to assess the severity before deciding on repair or demolition.

Wooden Formwork vs Steel Formwork

With construction industry development, steel formwork appeared as an alternative to wood. Each type has its advantages, disadvantages, and suitable use area.

Advantages of Wooden Formwork

Low initial cost compared to steel. Easy to cut and shape to any required sizes. Lightweight and easy to transport and install. Doesn't need heavy lifting equipment in small projects. Thermally insulates concrete in cold weather which helps curing. Available everywhere and easy to obtain. Suitable for complex shapes and special designs.

Disadvantages of Wooden Formwork

Short lifespan and limited number of uses. Affected by moisture and may swell or shrink. Needs continuous maintenance and proper storage. May cause problems if used when worn out. Leaves marks of joints and nails on concrete surface. Takes longer to install and remove compared to steel.

Advantages of Steel Formwork

High durability and very long lifespan. Can be reused hundreds of times without significant damage. Gives a smooth and uniform concrete surface. Fast installation and removal thanks to ready design. Not affected by moisture or insects. High accuracy in dimensions and angles. Resistant to weather and outdoor storage.

Disadvantages of Steel Formwork

Very high initial cost that may not suit small projects. Heavy and needs lifting equipment. Less flexible in shaping for special sizes. Conducts heat quickly which may affect concrete in cold or hot weather. May rust if not properly maintained. Needs large storage space.

When to Choose Each Type

Wooden formwork is suitable for small and medium projects like villas and residential buildings. Also for complex shapes and special designs and when budget is limited. Steel formwork is suitable for large and repeated projects like towers, bridges, and dams. And when high accuracy and excellent finishing are needed and when budget for long-term investment is available.

Tips for Extending Wooden Formwork Life

Proper care of wooden formwork increases the number of uses and reduces costs in the long run.

Before Pouring

Inspect boards to ensure they're sound and free of cracks and large holes. Clean the surface from previous concrete residue. Paint the surface with release oil or anti-stick material before each pour. Seal any gaps between boards tightly. Ensure tight fixation and support.

During Removal

Use wooden or plastic tools for removal and avoid sharp metal tools. Don't drop or throw boards forcefully. Remove formwork after concrete gains sufficient strength, not before. Clean boards immediately after removal and don't let concrete dry on them.

Cleaning and Maintenance

Clean boards with a brush or pressure water to remove concrete residue. Don't use harsh chemicals that damage the outer layer. Repair any minor damage with waterproof putty. Paint cut edges with waterproof paint to prevent moisture absorption.

Proper Storage

Store boards horizontally not vertically to prevent bending. In a dry and shaded place away from direct sunlight and rain. Raise them off the ground using wooden props. Organize them neatly by size for easy later use.

Choosing the Right Wood for Each Use

The type of wood differs according to the concrete element, finishing requirements, and budget.

For Foundations

Regular timber boards can be used because foundations are underground and not visible. Regular plywood is a good choice for large foundations. The most important thing is tight sealing to prevent concrete leakage. Film-faced is not necessary unless the foundation is visible.

For Columns

Columns are a sensitive element and plywood in good condition is preferred. Film-faced gives a smooth surface that reduces finishing work. Ensure the four corners are tightly sealed and prevent any leakage. Use tie rods to strengthen large columns with cross-sections exceeding 50×50 cm.

For Slabs and Beams

Slabs need strong wood that can bear concrete weight without bending. 18 mm thickness is the minimum for slabs. Film-faced is important for visible slabs without a false ceiling. Formwork should be supported with sufficient props at regular distances.

For Architectural Exposed Concrete

Requires the best plywood types which is HDO or high-quality film-faced. The surface must be perfect without any defects or scratches. May need new formwork for each pour to get the best result. Use high-quality release agents to prevent any sticking.

Tips for Property Owners When Dealing with Contractors

As a property owner, you have the right to monitor the quality of formwork used in building your home.

What You Should Request

Specify in the contract the use of plywood of specific quality, not just any available wood. Set the maximum acceptable number of wood uses. Ask to see the wood before pouring to confirm its condition. Require an engineer or supervisor during carpentry and pouring work.

Warning Signs

Pay attention if the wood is worn and full of holes from previous uses. If there are obvious gaps between boards. If the wood is swollen or warped. If the contractor refuses to replace damaged wood. If honeycombing appeared in previous pours and wood wasn't changed.

Your Rights

You have the right to refuse pouring if formwork is in poor condition. You have the right to request repair or demolition of any element with severe honeycombing. You have the right to hire a consulting engineer to evaluate work quality. You have the right to withhold part of payments until pour quality is confirmed.

Price and Cost Comparison

Understanding formwork economics helps you make the right decision.

Wooden Formwork Costs

Timber boards are the cheapest costing approximately 40 to 60 SAR per square meter. Regular plywood costs 60 to 100 SAR per sheet of 244×122 cm. Film-faced costs 100 to 200 SAR per sheet depending on quality and thickness. Add the cost of props, crossbeams, nails, and clamps.

Actual Cost Per Pour

If you use a film-faced sheet at 150 SAR for 30 pours, the cost is 5 SAR per pour. If you use a timber sheet at 50 SAR for 5 pours, the cost is 10 SAR per pour. Although film-faced is more expensive initially, it's more economical in the long run. This is in addition to better finishing quality and saving repair costs.

When is Quality Investment Worthwhile

For contractors executing multiple projects, investing in high-quality wood saves in the long run. For an owner building one house, medium-quality wood may be sufficient with good monitoring. For projects requiring high finishing, investing in film-faced is necessary.

Frequently Asked Questions

How many times can wood be used for pouring?

It depends on the type of wood. Timber boards 4 to 6 times. Regular plywood 8 to 15 times. Film-faced 20 to 50 times or more with good care.

What causes voids in columns after pouring?

This is called honeycombing and its causes are multiple, the main ones being insufficient use of vibrator, gaps in formwork leaking mortar, dense reinforcement, or pouring concrete from high elevation.

Is honeycombing dangerous?

Yes, honeycombing weakens concrete and exposes steel to rust. In severe cases especially in columns, it may require demolition and re-pouring. An engineer should be consulted to assess the situation.

What is the best type of wood for pouring columns?

18 mm thick film-faced plywood is the best because it gives a smooth surface, handles multiple uses, and reduces the possibility of leakage and honeycombing.

Is steel formwork better than wooden?

Each type has its advantages. Steel is better for large and repeated projects and gives better finishing. Wooden is cheaper and more flexible and suitable for small projects and special shapes.

How do I maintain wood for longer?

Clean it immediately after each pour, paint it with release oil before use, store it horizontally in a dry and shaded place, and paint cut edges with waterproof paint.

When do I know wood needs replacement?

When cracks appear or swelling or peeling of the outer layer or many holes or inability to seal tightly between boards.

Can any available wood be used for pouring?

Not recommended. Suitable formwork woods like timber boards or plywood should be used. Using unsuitable woods may cause concrete problems.

Conclusion

Reusing wood in concrete pouring is an acceptable and common practice but with specific conditions. The key is using wood of appropriate quality, adhering to the specified number of uses for each type, and proper care with cleaning and storage. Worn-out wood is one of the causes of honeycombing which is considered one of the most dangerous concrete defects threatening building safety. Invest in good wood like film-faced for important projects as it's more economical in the long run and ensures better quality. Monitor formwork quality in your project and don't hesitate to refuse using damaged wood no matter the pressure from the contractor. Your home's safety is more important than saving a few riyals on wood costs.