Modern Construction Methods 2025: Are "Prefab" and "3D Printed" Houses Durable or Fragile? The Complete Truth

Comprehensive technical analysis of modern construction methods in Saudi Arabia: Precast concrete, 3D printing, and tunnel formwork. Comparing durability, insulation, and cost with traditional construction. Will they really withstand sandstorms?

Introduction: The Question That Scares Every Citizen Thinking About Building

Almost every week, the Ministry of Housing announces a new project using "modern construction technologies." You hear about houses built in 48 hours, buildings manufactured in factories then assembled like Lego pieces, and giant printers that "print" entire homes!

But the question on every citizen's mind: Are these houses really strong? Will they withstand the brutal summer heat? Will they block the neighbors' noise? And most importantly: Will they blow away with the first sandstorm?!

In this comprehensive technical analysis, we put each technology under the microscope, compare it with the traditional construction we know, and answer all your questions with numbers and facts from official sources and real experiences.

First: Understanding the Fundamental Difference - What Is Modern Construction Anyway?

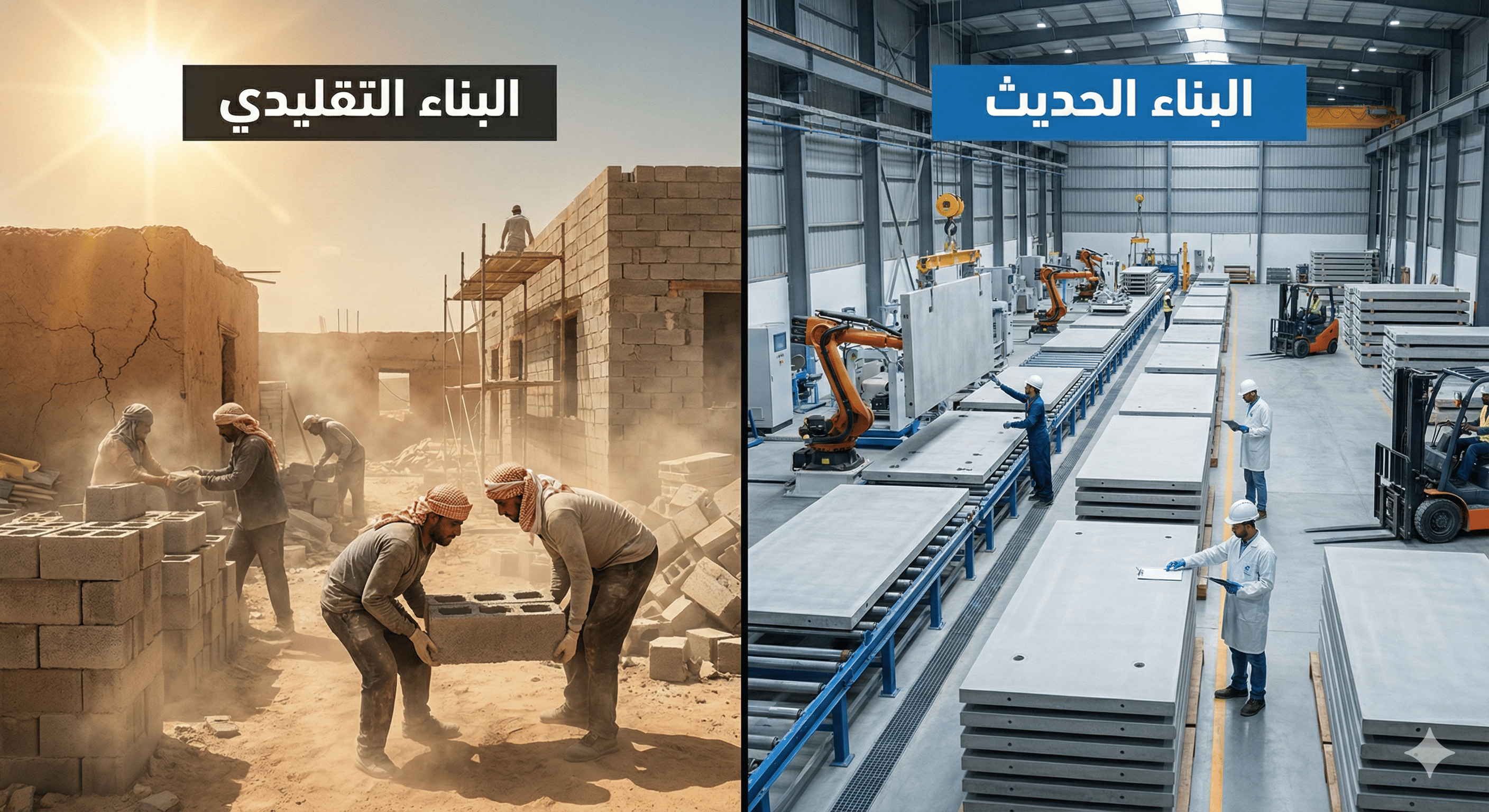

Traditional Construction: What We All Know

Traditional construction is what we've seen all our lives: workers pouring concrete on-site, laying blocks, mixing cement by hand, and building walls brick by brick. This method has existed for decades with its advantages: flexibility in modifications, availability of materials and labor everywhere.

But it has serious problems too: Quality depends 100% on the worker's skill! If the worker is tired or unskilled, cracks and honeycombing will appear in the walls. This is a real problem in Saudi Arabia where experts complain that "most construction sector workers are amateurs and unqualified."

Modern Construction: Factory-Controlled Manufacturing

The basic idea is simple: Instead of pouring concrete on-site under the scorching sun with workers who may not be skilled, why not manufacture everything in an air-conditioned factory, under engineers' supervision, with precise machines, then transport the ready pieces to the site and assemble them like a puzzle?

This is exactly what happens in modern construction. The result: uniform quality, incredible speed, less waste, and lower cost in the long run.

Second: The Six Officially Approved Technologies in Saudi Arabia

The Ministry of Municipal and Housing Affairs launched the "Modern Construction Initiative" and approved 6 main technologies. Let's explain each one in simple terms:

1. Precast Concrete

Imagine buying a ready-made wall from the factory instead of building it at your site! That's exactly what happens. Concrete is poured into perfect molds inside the factory, steam-cured to reach maximum strength, then transported to the site and installed with cranes.

The major advantage: The piece that comes out of the factory is 100% perfect because it was made under controlled conditions. No honeycombing, no voids, no cracks. The compressive strength of factory-made concrete reaches 4 times that of concrete poured on-site!

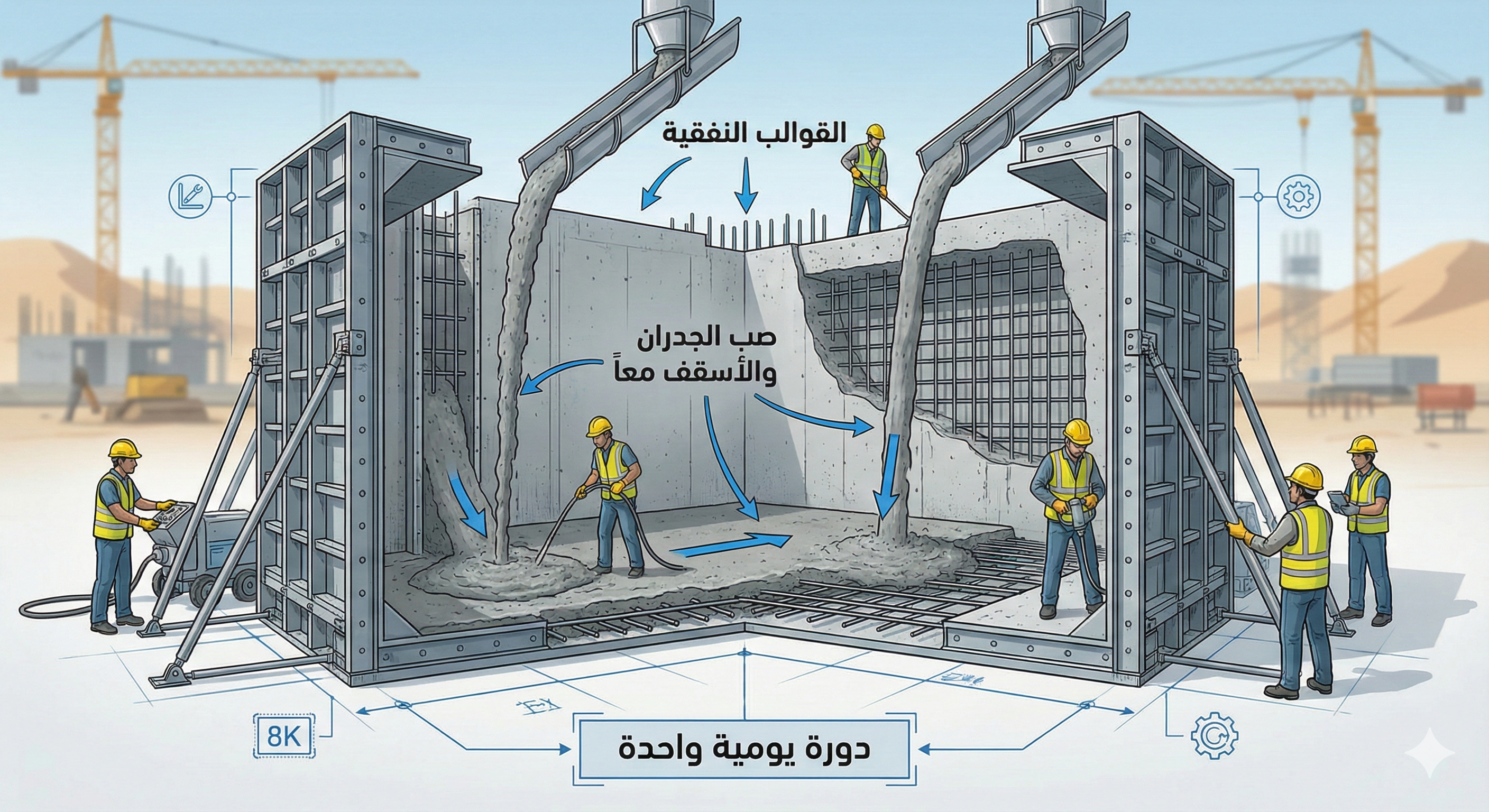

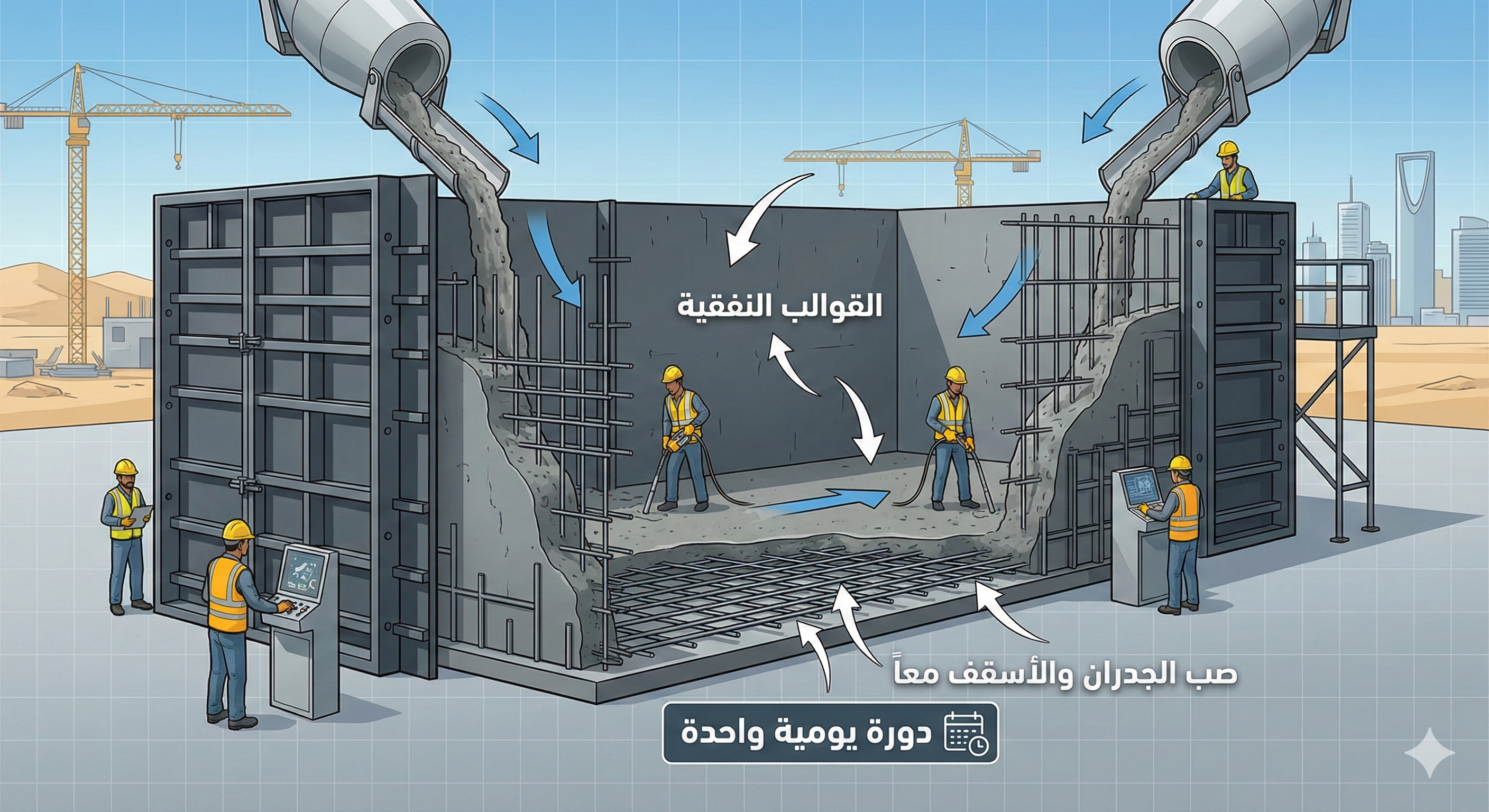

2. Tunnel Formwork

This technology is very clever: Instead of pouring walls first then ceilings, both are poured together in one operation! The forms are shaped like an inverted L, forming a "tunnel" where concrete is poured all at once.

The amazing result: An entire floor can be finished every day! A 10-story building is completed in just 20-30 days. Most importantly: These buildings are "earthquake-resistant" because walls and ceilings are connected as one solid mass.

3. 3D Printing

Yes, a giant printer prints your house! Imagine a printer the size of a football field, pumping special concrete layer by layer until the wall is complete. The first printed house in Saudi Arabia (and the Middle East) was built in Riyadh in just 48 hours!

The numbers are amazing: The printer builds at a speed of 30-100 cm per second, needs only 3 workers to supervise, and the strength of printed walls is 4 times traditional walls!

4. Lightweight Cellular Concrete

Concrete containing 80% air voids! It sounds crazy, but it's genius. These voids make the material very light (reducing weight by 83%) and at the same time provide excellent thermal insulation because air is a natural insulator.

5. Insulated Concrete Forms (ICF)

Imagine a concrete "sandwich": insulation layer, then concrete, then another insulation layer. These units come ready from the factory with integrated insulation. Result: 40% savings on electricity bills!

6. Light Steel Frame

A lightweight steel structure wrapped with insulating panels. Very quick to install, ideal for villas and medium-rise buildings. High durability with 60% weight reduction.

Third: The Most Important Question - Are These Houses Really Durable?

Earthquake Resistance Test

Buildings constructed with tunnel formwork technology have proven their resistance to earthquakes reaching 8 degrees on the Richter scale! The reason: Walls and ceilings are connected as one solid block, not separate pieces tied together.

In China, a house was built with 3D printing and withstood an 8 Richter earthquake without any damage. This is not a marketing claim, but actual test results.

Fire Resistance Test

Precast concrete features high fire resistance ranging from 2-4 hours. The reason: Precise control of concrete cover thickness from all sides in the factory, with no weak points.

Crack Test

Here, modern construction excels by a large margin. Cracks in traditional construction usually result from: concrete mixing errors, improper compaction, or lack of water curing. In the factory, all these processes are automated and precisely monitored, leaving no room for human error.

Fourth: Thermal and Sound Insulation - The Real Test

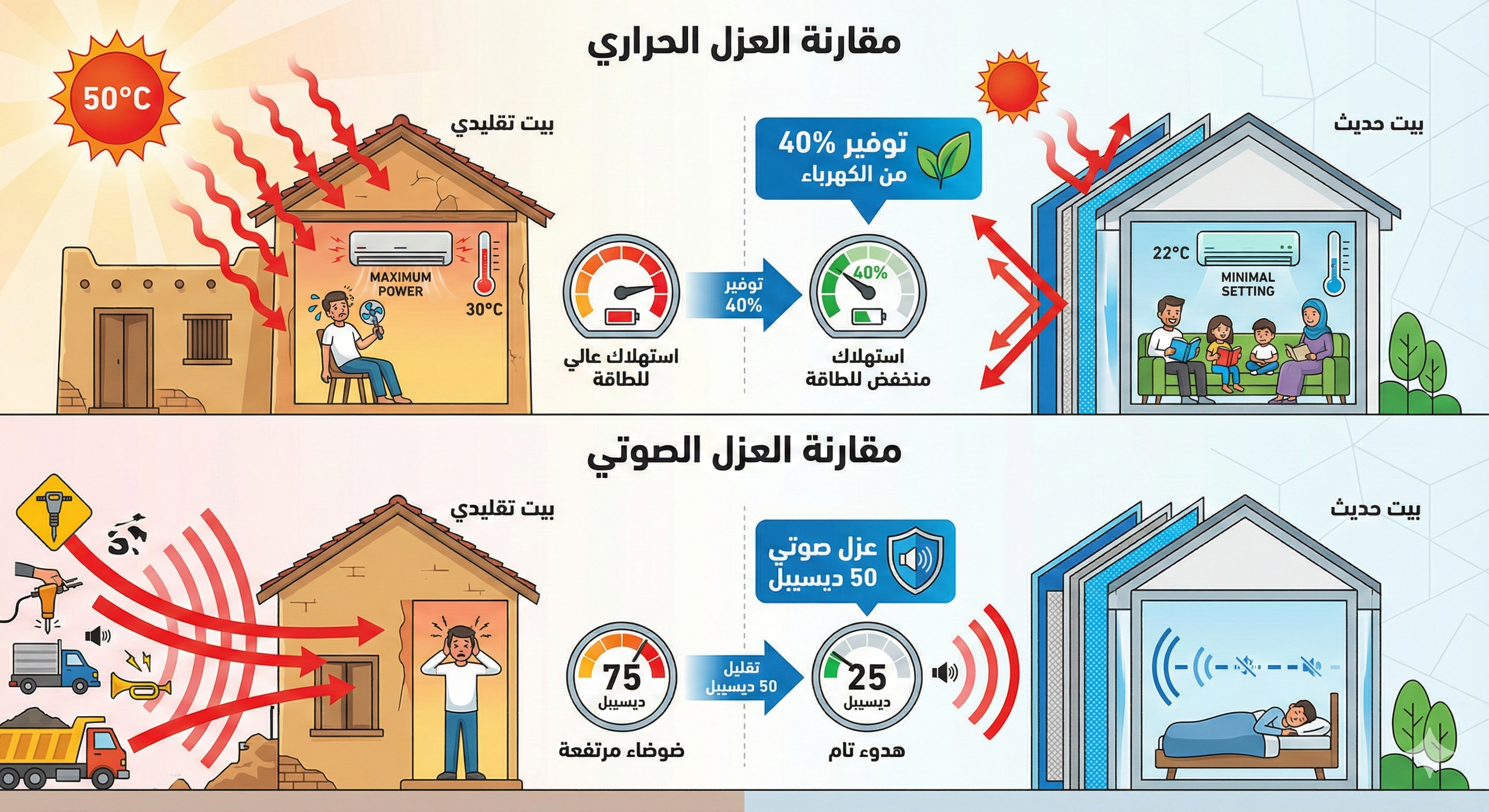

Thermal Insulation: Will It Protect You from 50-Degree Heat?

In Saudi Arabia where summer temperatures exceed 50°C, thermal insulation is not a luxury but a vital necessity. Modern construction excels here clearly:

Insulated Concrete Forms (ICF) save 40% on electricity bills compared to traditional construction. Cellular concrete with its air voids acts as a natural insulator. Most importantly: Insulation is integrated at the factory, not an "addition" that might be skipped or installed incorrectly.

Experts estimate annual electricity bill savings of 25-40%, meaning the initial cost difference (if any) is recovered within a few years.

Sound Insulation: Will You Hear Your Neighbor?

Tunnel formwork achieves sound insulation up to 50 decibels! For comparison, normal conversation volume is about 60 decibels. This means tunnel formwork walls almost completely eliminate neighbors' sounds.

The reason: Thick solid concrete walls are much better at absorbing sound than traditional hollow block walls.

Fifth: Cost and Speed - The Truth in Numbers

Is Modern Construction Really Cheaper?

The surprising answer: Yes! Prefab houses are 20-40% cheaper than traditional construction for medium sizes. A ready-made concrete house of 250 square meters starts from SAR 595,000, while the same area with traditional construction may exceed SAR 750,000.

But real savings come from several sources: time savings (months instead of a year), annual electricity bill savings (25-40%), reduced maintenance costs (no cracks or leaks), and longer lifespan (50+ years).

Incredible Speed

Here's the biggest and clearest difference:

Traditional construction takes 6-18 months to finish a medium villa. Modern construction takes only weeks to 3 months! A 3D printer builds a house structure in 48 hours. Tunnel formwork finishes an entire floor every day.

This speed is not at the expense of quality, but the opposite: Speed comes from pre-manufacturing at the factory, and quality is higher because everything is done under strict supervision.

Sixth: How Does Modern Construction Solve the Unskilled Labor Problem?

The Real Problem in Traditional Construction

Experts say: "Construction sector workers in Saudi Arabia are amateurs and qualified ones are rare." The problem is that homeowners are forced to deal with "street contractors" who are uncertified, using cheap untrained labor, resulting in "unsound" houses that need constant repairs.

This is not theoretical talk. How many times have you heard about a neighbor discovering cracks in their new house? Or water leaking from the roof after the first rain? Or failed thermal insulation that made the electricity bill astronomical?

The Solution: Removing the Human Factor from the Equation

In modern construction, most work is done in the factory with machines. The human worker's role is "supervision" not "execution." The machine doesn't get tired, doesn't make mixing ratio mistakes, doesn't forget to compact concrete, and doesn't stop water curing.

Even 3D printing needs only 3 workers for supervision, while traditional construction needs dozens of workers. This means: lower labor cost, fewer errors, higher quality.

Seventh: Official Statistics from the Ministry of Housing

Numbers Proving Successful Transformation

According to Modern Construction Initiative reports: There are currently 44 factories working in modern construction technologies, production capacity exceeds 40,000 housing units annually, 58% of Sakani program projects now use modern construction, more than 109 housing projects have been supported with modern technologies, and more than 134,264 housing units have been produced.

Real Projects on the Ground

In Al-Jawan suburb north of Riyadh, 8 out of 12 housing projects use modern construction. In Makkah region, 16 projects with more than 56,000 housing units (42% of total units). NEOM and The Line project uses 100% modern technologies with robots!

Eighth: Frequently Asked Questions - Honest Answers

Will the Prefab House "Collapse" Over Time?

No. The lifespan of prefab concrete houses reaches 50+ years with proper periodic maintenance. This is longer than many traditional houses that suffer from structural problems after a few years due to poor execution.

Can I Modify the Prefab House in the Future?

This is an important point: Modifications in modern construction are harder than traditional. You can't easily "break a wall" or "open a new window." Therefore, good planning before construction is essential. But this is not a flaw as much as an incentive for proper planning from the start.

Is Modern Construction Available in All Saudi Cities?

Currently, focus is on major cities: Riyadh, Jeddah, Dammam, Makkah. But with increasing number of factories (44 currently operating and 50 in qualification stages), coverage is constantly expanding.

How Do I Ensure the Executing Company's Quality?

Make sure the company is certified by the Modern Construction Initiative under the Ministry of Housing. Ask for quality certificates and tests. Visit the company's previous projects if possible. And ensure there's a written guarantee on the structural framework.

Are Electricity Bills Really Lower?

Yes, experts confirm 25-40% savings on electricity bills thanks to integrated thermal insulation. In Saudi Arabia's hot climate, this means saving thousands of riyals annually.

Conclusion: Should You Choose Modern Construction?

The answer depends on your priorities:

Choose modern construction if: You want guaranteed quality without surprises, you need speed in completion, you care about saving on electricity bills, you don't plan major future modifications, or you want a house that will last for your children and grandchildren.

Traditional construction may suit you if: You plan many continuous modifications, you have strong engineering supervision ensuring execution quality, or you're in a remote area that modern construction services don't reach.

The truth you should know: Modern construction is not a "trend" that will fade, but the future of construction worldwide. Saudi Arabia is investing billions to localize these technologies, and mega projects like NEOM are being built entirely with modern technologies.

The question is not "Is modern construction good?" but "When will you benefit from it?"

At Raghdan, we help you understand your options and make the right decision for your needs. Browse our property listings and benefit from our expertise in the Saudi market.